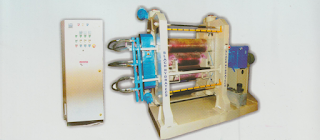

Rubber Processing Machinery Manufacturer in india Slach Hydratecs Equipment Private Limited Slach Hydratecs can go the extra miles in order to ensure complete customer satisfaction and value for their money. The company remains focused to recognize and adopt the trends of contemporary global markets. Our products - S lach Hydratecs Equipment Pvt Ltd, Manufacturers, Rubber Mixing Mill Manufacturers, Rubber Processing Machine Manufacturers, Rubber Mixing Mill Exporters, Rubber Refining Mill Manufacturers, Rubber Refining Mill Exporters, Rubber Bale Cutter Manufacturers, Rubber Injection Moulding Machine Manufacturers, Rubber Calender Machine Manufacturers, Internal Rubber Mixer Manufacturers, Rubber Mixing Mill Suppliers, Undrive Mixing Mill Suppliers, Plastic Injection Machines .